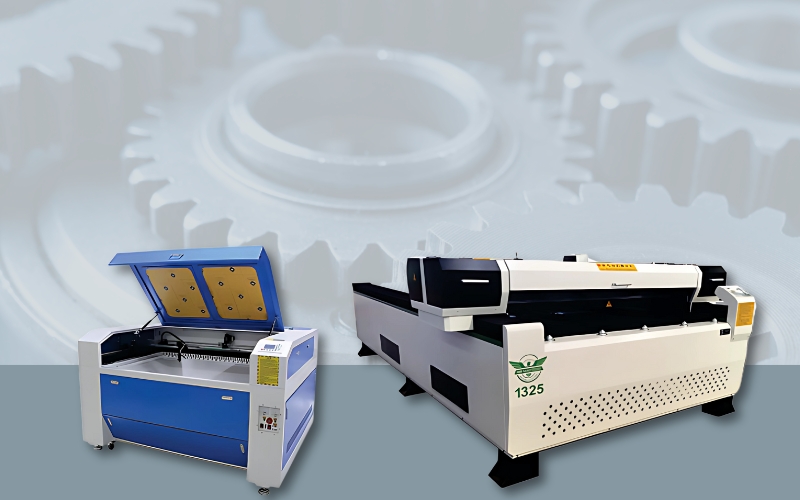

In today’s fast-paced industrial world, precision, speed, and reliability are non-negotiable. One tool that is revolutionizing modern manufacturing and design is the Co2 Laser Cutting Machine. Whether you’re working with acrylic, wood, leather, glass, or certain metals, a Co2 Laser Cutter Engraver offers unparalleled cutting and engraving capabilities. In this article, we’ll explore the features, applications, and benefits of the RBMactech Co2 Laser Machine, a leader in the industry.

What is a Co2 Laser Cutting Machine?

A Co2 Laser Cutting Machine is a type of gas laser that uses a carbon dioxide gas mixture as the active medium. This laser is highly efficient in cutting non-metallic materials and is used extensively across industries for its fine detailing and smooth edge quality.

At the heart of it, the Co2 Laser Cutter works by focusing a laser beam through a lens onto the material, heating and vaporizing it into a precise cut. From delicate engravings to complex designs, the Co2 Laser Engraving Machine offers extreme precision with minimal material wastage.

Why Choose RBMactech Co2 Laser Machine?

When it comes to choosing a reliable and high-performance Co2 Laser Cutting Machine, RBMactech Co2 Laser Machine stands out. Here’s why:

- High Cutting Accuracy: With precision engineering and software integration, RBMactech delivers optimal performance.

- Durability: Designed for long-term industrial usage.

- Multi-Material Capability: Works efficiently on wood, acrylic, leather, rubber, textiles, and more.

- User-Friendly Interface: Easy-to-operate software that enables both beginners and professionals to operate seamlessly.

As a leading Co2 Laser Machine Manufacturer, RBMactech ensures every unit meets international quality standards.

Applications of Co2 Laser Cutter Engraver

The versatility of a Co2 Laser Cutter Engraver makes it ideal for multiple applications, including:

- Advertising and Signage: For precision-cut acrylic and plastic signs.

- Textile and Leather Industries: Engraving patterns and cutting complex shapes.

- Packaging: Engraving logos, barcodes, and custom artwork.

- Craftsmanship: Creating intricate designs in wood and glass.

Educational Institutions: Widely used in design and engineering departments.

Difference Between Co2 Laser Cutting, Engraving, and Marking

Although often used interchangeably, there are distinctions between Co2 Laser Cutting, Co2 Laser Engraving, and Co2 Laser Marking:

- Cutting: Completely cuts through the material.

- Engraving: Removes layers without penetrating all the way.

- Marking: Alters the surface to create visible marks, usually used for barcodes or serial numbers.

RBMactech offers machines tailored for all three purposes, ensuring users can switch seamlessly between applications.

Co2 Metal Laser Cutting Machine: Is It Possible?

Although CO2 laser Machines are mainly used for non-metallic materials, with certain adjustments and coating techniques, they can be used for thin sheet metals like aluminum and stainless steel. The Co2 Metal Laser Cutting Machine by RBMactech is engineered with this versatility in mind—perfect for light-duty metallic applications combined with robust non-metal performance.

Benefits of RBMactech Co2 Laser Cutting Machine

- High-Speed Operations: Complete large projects in a fraction of the time.

- Cost-Efficiency: Minimal power consumption and material wastage.

- Precision & Consistency: Perfect for replicating designs without error.

- Compact Designs: Save space while boosting productivity.

- After-Sales Support: As a top Co2 Laser Machine Manufacturer, RBMactech offers full training, maintenance, and support services.

Choosing the Right Co2 Laser Engraving Machine

While buying a Co2 Laser Engraving Machine, consider the following:

- Wattage Power: Determines the depth and speed of cutting.

- Bed Size: Choose according to the materials you plan to work on.

- Cooling System: Essential for long operation periods.

- Software Compatibility: Ensure it supports popular design formats like DXF, SVG, and AI.

With RBMactech’s range, you’ll find every feature you need for industrial or creative applications.

Conclusion

Whether you’re an entrepreneur, industrial manufacturer, designer, or hobbyist, investing in a Co2 Laser Cutting Machine is a smart move. The RBMactech Co2 Laser Machine offers exceptional quality, performance, and flexibility. From Co2 Laser Marking to engraving and cutting, these machines redefine precision manufacturing.

As a leading Co2 Laser Machine Manufacturer, RBMactech is dedicated to delivering the best in class Co2 Laser Cutter Engraver and Co2 Metal Laser Cutting Machine solutions that match the needs of various industries.

FAQs

Co2 laser machines can cut wood, acrylic, leather, rubber, paper, and some coated metals. They are ideal for non-metallic materials.

Co2 laser machines can cut wood, acrylic, leather, rubber, paper, and some coated metals. They are ideal for non-metallic materials.

Yes, with the right power and coating techniques, you can engrave and mark thin metals. For heavy-duty metal, fiber lasers are preferred.

Typically, a high-quality Co2 laser tube lasts 1,500 to 10,000 hours, depending on usage and maintenance.

RBMactech machines are compatible with software like RDWorks, LaserGRBL, and LightBurn, supporting common file types like AI, DXF, SVG, and BMP.

RBMactech offers high-performance, durable machines with complete after-sales support, training, and customization options. They are industry leaders in India.